scroll and find out more...

Handling equipment - Receiving hopper | RH 12 Combi

Intake volume up to 8 m³, soil cleaning, picking and pre-grading.

The compact receiving hopper, type RH 12 Combi, especially suits medium sized farms. The hopper floor, which is made of soft rubber, the roller package consisting of PU spiral rollers and the infinitely drive enable maximum crop protection and optimum throughput. Several handling steps in the storage and preparation process can be combined in just one machine: Crop intake, soil cleaning, picking, power pre-grading and pre-grading. The machine can be assembled from a wide range of options to meet the customer's specific requirements. On the optional available roller picking table, the crop is conveyed in rotation, which provides an excellent picking possibility. Furthermore, the platform on both sides offers sufficient space and a perfect, safe stand to the picking staff. Depending on the requirements as regards accuracy of grading and gentle crop handling, the RH 12 Combi can be combined with a web grader or a one- resp. two-step coil unit, made of polyurethane.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

Highest crop protection

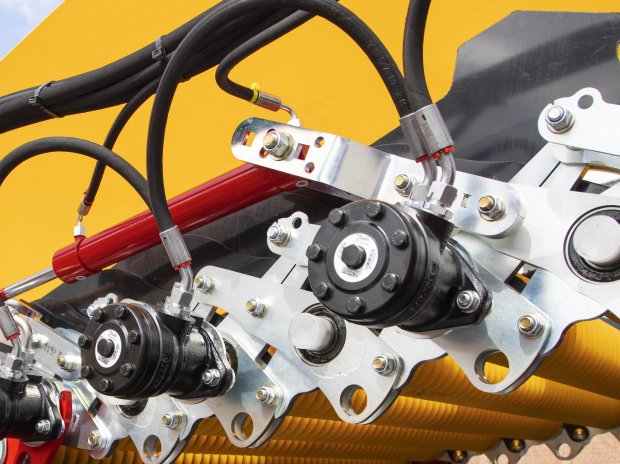

The soft, wear-resistant polyurethane (PU) spiral rollers achieve lowest impact on the crop and an effective separating performance.In addition, jammed stones and entangled haulm are avoided.

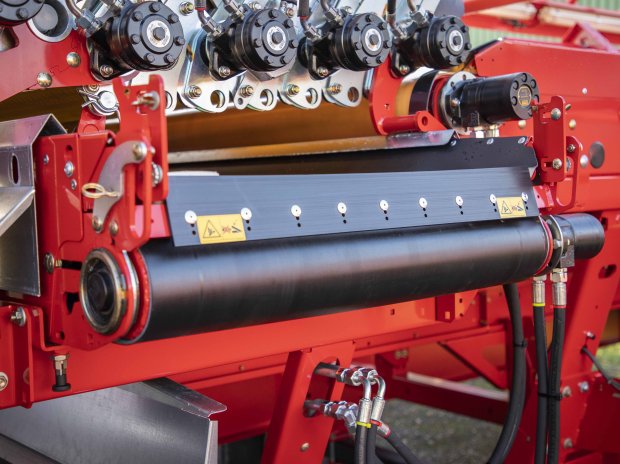

Ergonomically designed roller picking table

The roller picking table turns the crop while transferring, to assist picking.

Gentle crop transfer

Gentle transfer between the single units ensured by direct coupling.

Storing according to tuber size

Web grader WG 900 directly behind the picking table for the highest sorting accuracy.

Gentle pre-grading of the crop downstream of the picking table

The combination of a receiving hopper and subsequent pre-grading with PU spiral rollers is a unit for powerful and gentle crop handling.

Benefits

Front section (receiving)

Hopper floor / bunker floor

Soil cleaning and pre-grading

Crop discharge

Control Systems

Convenience

- Compactly designed receiving hopper, particularly suitable for narrow building arrangements

- Gentle intake due to soft rubber floor

- The special shape of the rubber-flights on the belt leads to optimum dragging effect and supports a high protection of the harvested crop.

- Optimum crop flow due to infinitely variable hopper floor speed

- Gentle crop discharge from the hopper floor onto the spiral coils.

- Gentle soil cleaning with PU spiral rollers

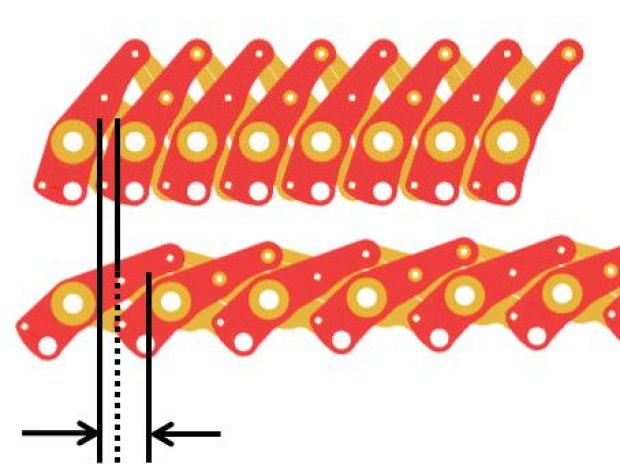

- Infinitely speed adjustment in two packets (coil 1, 3, 5 and 2, 4, 6) ensure an optimal and crop protective soil separation

- Quick adaption of the soil cleaning to varying amount of trash via infinitely distance adjustment of the PU-coils

- Perfect transfer in variable conditions: A constant and protective crop flow from the soil cleaning unit onto the roller picking table is even ensured, when the distance of the rollers of the cleaning unit are adjusted. This is made possible by a mechanical coupling of the cleaning unit and the roller picking table.

- Ergonomically designed picking platform.

- The receiving hopper RH 12 Combi can be used variably thanks to a wide range of different sorting or pre-grading units. The optional use of a web grader WG 900 or additional PU spiral rollers for pre-grading behind the picking table enables the crop stream to be fractionated into two or three fractions of different size.

- Maintenance free direct drives

- Comfortable operation via operator terminal type GBT 831

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

- Soft rubber belt with 15 mm high flights

- Height adjustable intake flap

- Infinitely adjustable hopper floor speed

- Soil cleaning with 6 PU spiral coils

- Hydraulic distance adjustment of the soil cleaning unit

- Infinitely speed adjustment of the PU cleaning rollers

- Difference speed setting of the PU spiral coils

- Soil cross conveyor

- Picking table with belt, for up to 4 persons

- Picking platform, incl. 2 stairs

- 2 lights

- Emergency stop via cable control

- Infinitely adjustable picking table web speed

- Crop cross conveyor

- Operator terminal GBT 831 (incl. 8 m connecting cable)

Technical data

5221-010 RH 12-40 Combi

| Intake | |

|---|---|

| Intake height (min.) | 900 mm |

| Intake height (max.) | 1200 mm |

| Intake width | 2900 mm |

| Hopper floor width | 1400 mm |

| Hopper floor length | 4000 mm |

| Hopper floor speed | 1 - 5 m/min |

| Capacity | 6 m³ |

| Soil cleaning / pre-grading | |

| Width | 1200 mm |

| Number of coils | 6 |

| Coil distance | 5 - 45 mm |

| Power supply | |

| Voltage | 400 V |

| Frequency | 50 Hz |

| Power with crop cross conveyor following picking table (standard) | 11 kW |

| Power with F6 following picking table (option) | 15 kW |

| Output with F7F6 following picking table (option) | kW |

| Output with WG 900 following picking table (option) | 11 kW |

5221-020 RH 12-60 Combi

| Intake | |

|---|---|

| Intake height (min.) | 900 mm |

| Intake height (max.) | 1200 mm |

| Intake width | 2900 mm |

| Hopper floor width | 1400 mm |

| Hopper floor length | 6000 mm |

| Hopper floor speed | 1 - 5 m/min |

| Capacity | 8 m³ |

| Soil cleaning / pre-grading | |

| Width | 1200 mm |

| Number of coils | 6 |

| Coil distance | 5 - 45 mm |

| Power supply | |

| Voltage | 400 V |

| Frequency | 50 Hz |

| Power with crop cross conveyor following picking table (standard) | 11 kW |

| Power with F6 following picking table (option) | 15 kW |

| Output with F7F6 following picking table (option) | 15 kW |

| Output with WG 900 following picking table (option) | 11 kW |