scroll and find out more...

Planting technology - Cup planter | GL 860 Compacta

8-row, 6 t hopper, foldable, for areas with smaller and large fields

The GL 860 Compacta unites all the advantages of a trailed 8-row potato planter with a compact potato planter. Highest acreage performance combined with a fast change of fields make the machine to the most efficient potato planter in the market. The special folding system for road transport makes it possible. A comprehensive list of features makes the machine particularly attractive for agricultural contractors and individual customers in small and large structured cultivation regions. The GRIMME professional planting element is the right choice for a very precise and even planting distance. Different setting options of the machine together with good calibrated seed enable a high planting speed. The ISOBUS operator terminal CCI 800 or CCI 1200 with intuitive user interface GDI and various diagnostic options offer a high level of operating comfort and provides relief for the driver.

- Please select...

- Highlights

- Benefits

- Images / video clips

- Configuration

- Downloads

Fast movement between fields

To enable a fast transfer from field to field, the machine with a row width of 75 cm can be folded to a width of 3,29 m.

Ridge shaping on light soils

For an improved water absorption on light soils, cage rollers can be used in combination with spring-loaded ridging bodies.

Combined plant protection

GRIMME tank system TS 820, authorized for liquid chemicals to be applied onto the seed potatoes and/or into the furrow.

Improved capillarity

Ridge pressure rollers improve capillarity on light soils by slightly soil recompaction of the ridge crown.

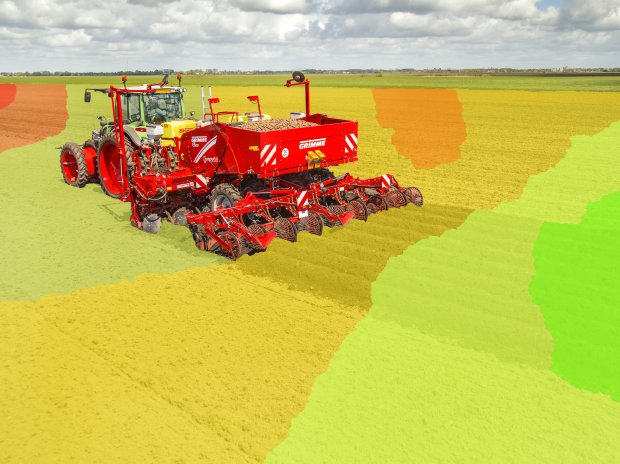

Sub-area specific planting.

When using application cards when planting potatoes, the planting distances in cm can be set variably over the entire width of the machine.

Video: The cup planter GL 860 at work

Benefits

- The powerful planting element enables a simple adaption to the tuber size and ensures therefore an exact spacing.

- For a road transport and a fast change from field to field the machine with 75 cm row width is foldable to a transport width of 3.29 m.

- Large range of options for an individual configuration of the machine.

- Tuber spacing adjustment from the drivers' cab via the hydraulic single row drive.

- Less seed potatoes are required with the automatic single row deactivation of the planting elements with Section Control.

- Variable Rate Control (VRC): By use of electronic application maps the machine is able to realise precise, variable tuber spacing for each single row.

- Clever Planting: Increased share of marketable crop due to an improved, even growth and tuber size in the rows next to the spray tracks. This is achieved by an infinitely adjustable, reduced tuber spacing and reduces the competition for light and nutrients along the spray tracks.

- The deep lowering (option) of the tipping hopper enables direct filling from the trailer.

- A shaping board can be used for building ridges with specific characteristics from loose to firm soil with a smooth surface. There are several versions for ridge shaping bodies available for a perfect adaptation to different soil conditions, ridge shapes and ridge volumes.

- For an improved water absorption on light soils, cage rollers can be used in combination with spring-loaded ridging bodies. The cage rollers provide a light, airy ridge with an open-pored surface.

- The approved GRIMME tank system ensures even application of the tuber with liquid chemicals and offers the driver many comfort functions.

- Simultaneous application of liquid chemicals and granulates for an optimal start of the vegetation.

- The ISOBUS operator terminals CCI 800 and CCI 1200, with intuitive operating interface GDI and various diagnostic options, offer a high operator comfort.

Specifications

You'll find all the information about the standard features of the machine here.

Configuration

- Hydraulic single row driven planting elements

- Hydraulically operated lane marker, incl. sequence switch (hydraulic change-over valve)

- Optimum feeding of all planting elements with sensor operated feed conveyor

- Quick unlock to change planting belts

- Platform with ladder for a better accessibility during maintenance and easier adjustments

- Planting belt with cups of choice

- Trailed furrow opener in the parallelogram, depth control via 1 feeler wheel for 2 furrow openers

- Individually spring loaded and ball bearing mounted, large, serrated covering discs, with a diameter of 510 mm.

- Row width 75 cm

- Lift up drawbar

- Telescoping drawbar to fold-in the machine

- Chassis with pivot axle and 4 wheels

- Wheels 12.4 - 24 AS

- Hopper capacity 6000 kg

- Air brakes or hydraulic brakes

- ISOBUS operator terminal CCI 800

Technical data

GL 860 Compacta

| Dimensions | |

|---|---|

| Length without shaping board in working / transport position | 5460 / 6600 mm |

| Length with shaping board in working / transport position | 6485 / 7385 mm |

| Length with cage roller in working / transport position | 6270 / 7410 mm |

| Length with spraying track lever in working / transport position | 6620 / 7760 mm |

| Width at row width 75 cm in working / transport position | 6200 / 3295 mm |

| Width from row width 76.2 cm in working / transport position | 6640 / 3650 mm |

| Width from row width 85 cm in working / transport position | 7350 / 4000 mm |

| Height in working / transport position | 2385 / 3660 mm |

| Filling height tipping hopper low | 1855 mm |

| Filling height tipping hopper flat | 2070 mm |

| Overlapping length at the rear with shaping board | 540 mm |

| Overlapping length at the rear with cage roller | 810 mm |

| Overlapping length at the rear with spraying track lever | 640 mm |

| Weight | |

| Empty weight with basic configuration | 5150 kg |

| Empty weight with cage roller | 6850 kg |

| Working width | |

| Row width | 75 - 91,4 cm |

| Row width | 34 / 36 " |

| Number of rows | 8 |

| Tractor attachment | |

| Drawbar eye / low hitch | x |

| Low hitch | x |

| Low hitch ball bearing (K 80) | x |

| Bunker | |

| Capacity | 6000 kg |

| Wheels | |

| Wheels | 12.4-24 AS |

| Tractor requirements | |

| Engine power (min.) | 108 kW |

| Oil flow | 50 l/min |

| Required control valves (single acting) | 1 |

| Non-pressurized return flow | 1 |